In today’s rapidly evolving technological landscape, the concept of digital twins has emerged as a game-changer. By creating virtual replicas of physical assets, processes, or systems, digital twins are revolutionizing how we monitor, analyze, and optimize the world around us. From manufacturing to healthcare, the applications of digital twins are broad and transformative. Let’s dive into what digital twins are, how they work, and why they’re becoming an essential part of industries worldwide.

What Is a Digital Twin?

A digital twin is a virtual model or replica of a physical object, system, or process. It collects real-time data through sensors and other data sources to simulate the behavior, performance, and dynamics of the physical counterpart. The digital twin allows businesses to analyze, monitor, and optimize the real-world entity without the need for direct interaction with the physical version.

The key idea behind digital twins is creating a bridge between the physical and digital worlds. By using data from the real-world object, digital twins can predict potential issues, improve decision-making, and increase operational efficiency.

How Do Digital Twins Work?

The process of creating and utilizing a digital twin involves a few key steps:

1. Data Collection

- The physical asset or process is equipped with sensors that gather real-time data. This can include data about performance, temperature, location, speed, and other metrics. The more sensors and data points available, the more accurate and comprehensive the digital twin will be.

2. Data Transmission

- The data collected by the sensors is transmitted to a central system or cloud platform. This data is processed and used to update the digital model of the physical asset or process in real-time.

3. Modeling and Simulation

- Using software and algorithms, the data is used to create an accurate digital representation of the physical entity. This virtual model simulates how the real-world object behaves under different conditions.

4. Analysis and Insights

- Once the digital twin is up and running, businesses can analyze the data and gain insights into the performance, health, and behavior of the physical asset. This can involve monitoring for anomalies, predicting future issues, or running simulations to optimize performance.

5. Feedback Loop

- The data from the digital twin is fed back into the physical system to make adjustments or improvements. This real-time feedback loop allows for continuous optimization and ensures that the digital twin remains a true representation of the physical entity.

Types of Digital Twins

Digital twins come in various forms depending on the application and complexity of the system being replicated. The three main types of digital twins are:

1. Component Digital Twins

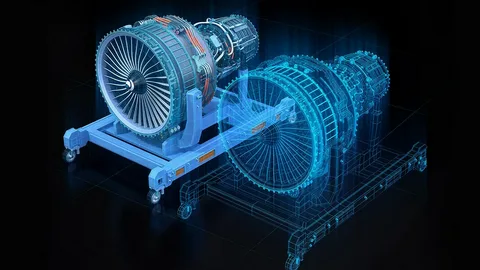

- These represent individual components or parts of a system. For example, a digital twin of a single engine component or a turbine blade. They provide insights into the performance of the specific part and can be used to detect wear and tear, optimize maintenance schedules, and predict failure.

2. Asset Digital Twins

- An asset digital twin represents a complete system or asset, such as a factory machine, a vehicle, or a piece of equipment. These twins provide a more comprehensive view of the performance and health of the asset as a whole, not just individual components.

3. System Digital Twins

- These twins represent entire systems, such as a smart city or a factory production line. System digital twins model the interactions between various components and processes to optimize overall system performance. They are often used for complex simulations, scenario testing, and predictive maintenance across interconnected systems.

Applications of Digital Twins

The potential applications of digital twins are vast and span across various industries. Here are some of the most significant and impactful use cases:

1. Manufacturing and Industry 4.0

- In manufacturing, digital twins are used to create virtual models of production lines and equipment. This allows manufacturers to monitor performance in real-time, predict equipment failures, and optimize production processes. Digital twins also enable predictive maintenance, reducing downtime and extending the lifespan of machinery.

2. Smart Cities

- Digital twins can be used to create virtual models of entire cities, incorporating data from buildings, traffic systems, utilities, and more. This allows city planners and officials to simulate and analyze traffic flow, energy consumption, waste management, and other systems, improving efficiency and sustainability.

3. Healthcare

- In healthcare, digital twins can create virtual models of patients or medical devices. For example, digital twins of patients can track vital signs, predict potential health risks, and guide personalized treatment plans. Digital twins of medical equipment ensure that machines like MRI scanners are performing optimally and are well-maintained.

4. Automotive and Aerospace

- In the automotive and aerospace industries, digital twins are used to simulate vehicle performance, from individual components to full vehicles. This allows for better designs, faster prototyping, and real-time monitoring of fleet performance, leading to enhanced safety and reliability.

5. Energy and Utilities

- Digital twins in energy and utilities can monitor infrastructure like power grids, oil rigs, or wind turbines. By creating digital models of these systems, energy providers can optimize energy distribution, predict failures, and ensure the safety and efficiency of their operations.

6. Construction and Architecture

- Digital twins are transforming the construction industry by enabling virtual modeling of buildings and infrastructure before construction begins. This allows for better planning, design validation, and project management. Once construction is complete, digital twins continue to provide value by monitoring building systems and ensuring optimal performance.

7. Retail

- In retail, digital twins can help optimize supply chains, track inventory, and personalize customer experiences. Virtual models of stores or warehouses can simulate customer behavior, product placement, and logistics to improve operations and sales.

Benefits of Digital Twins

Digital twins offer numerous benefits that drive their adoption across industries. Here are some of the key advantages:

1. Enhanced Decision-Making

- Digital twins provide real-time insights into the performance of physical assets and systems. This enables businesses to make data-driven decisions, optimize operations, and predict future outcomes more accurately.

2. Improved Efficiency

- By continuously monitoring and analyzing assets through digital twins, businesses can optimize performance, reduce waste, and improve resource utilization, leading to higher efficiency and lower operational costs.

3. Predictive Maintenance

- One of the most significant benefits of digital twins is predictive maintenance. By analyzing data from digital twins, businesses can predict equipment failures before they happen, reducing downtime and maintenance costs.

4. Reduced Risk

- Digital twins allow businesses to simulate and test different scenarios before making changes to real-world systems. This helps identify potential risks and optimize designs before they are implemented in the physical world, reducing costly mistakes and failures.

5. Customization and Personalization

- In industries like healthcare and retail, digital twins enable greater customization and personalization. By creating virtual models of individuals (e.g., patients or customers), businesses can offer more tailored services, products, or treatments.

Challenges of Digital Twins

Despite their many benefits, there are some challenges associated with digital twins:

1. Data Privacy and Security

- Digital twins rely on large amounts of data, including real-time sensor data. Ensuring that this data is secure and complies with privacy regulations is a critical concern.

2. Integration with Existing Systems

- Implementing digital twins often requires integrating with existing systems and infrastructure, which can be complex and costly. This may involve upgrading equipment or implementing new software solutions.

3. Data Management

- Managing the vast amount of data generated by digital twins can be a challenge. Organizations need robust data storage and processing capabilities to handle this information and extract meaningful insights.

4. Cost of Implementation

- While the long-term benefits of digital twins are significant, the initial investment required to implement and maintain digital twin technology can be high, especially for complex systems or large-scale applications.

The Future of Digital Twins

The future of digital twins looks incredibly promising, with technology continually evolving to offer even greater capabilities. Here are some trends that are shaping the future of digital twins:

1. AI and Machine Learning Integration

- The integration of AI and machine learning will make digital twins even smarter. These technologies will enable digital twins to learn from data, predict future behaviors more accurately, and make autonomous decisions based on real-time insights.

2. Greater Adoption in Various Industries

- As digital twin technology becomes more affordable and accessible, we can expect to see broader adoption across industries. Sectors like healthcare, retail, and energy are already seeing significant benefits, and other industries will soon follow.

3. IoT and 5G Connectivity

- The continued growth of the Internet of Things (IoT) and the rollout of 5G networks will further enhance digital twins by providing faster data transmission and enabling real-time updates from even more devices.

4. More Detailed and Complex Models

- As computing power increases, digital twins will become even more detailed and complex. This will allow for more precise simulations and predictions, further optimizing the systems they represent.

Final Thoughts

Digital twins are poised to reshape the way we interact with the physical world, offering unprecedented insights, efficiency, and opportunities for innovation. By creating digital replicas of real-world assets and systems, businesses can optimize operations, predict failures, and enhance decision-making. From manufacturing to healthcare, the potential of digital twins is immense, and as technology advances, we can expect them to become an even more integral part of our lives.

The future is digital, and digital twins are helping bring that future closer to reality!

4o mini